How to choose a gas sealing solution?

To select the best sealing material for a gas system its constituent factors must be considered, such as the type of gas, necessary compressibility, required sealing load or seal thickness.

Sealing solutions for gas applications

Gas regulators are used in a wide range of everyday household appliances. Their principal function is to maintain a consistent and safe gas pressure within the system. Given the critical nature of this task, it is essential to choose the correct sealing solution, offering high performance and reliability. In this context, it is necessary to consider that the structure of the gas regulator and the conditions in which it will be operate may vary considerably, and therefore the selected sealing material must be suited to the specific requirements.

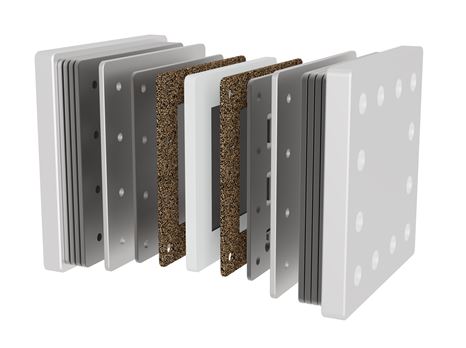

One of the principal advantages of the Amorim Tech Seal sealing solutions for gas regulators is the superior performance they offer in terms of conformability and load to seal, compared to traditional rubber seals.

Long-term ageing assessments have revealed that rubber seals often suffer from local fractures, bending and warping, due to lateral flow and thermal expansion. By contrast, Amorim Tech Seal cork composite joints retain their shape and have very low extrusion, preserving the integrity of the seal over time. This durability guarantees an effective seal, even under varying pressure and temperature conditions.

Cork's unique compressibility and micro-sealing characteristics also enable it to adapt to the uneven surface of the flange, providing an effective seal even with narrow joint widths (just 2 mm). Amorim Tech Seal solutions fulfil the requirements of various certifications, such as DVGW, NP44, EN 30.1.1, part 6.1.1.2 and JIA C001.

In the future, natural gas and low-carbon gases will play a crucial role in sustainable energy systems.

Amorim Cork Composites stands at the forefront of this transition, offering sustainable sealing solutions for natural gas, LPG or hydrogen applications. In addition to complying with the technical requirements of this type of application, the cork used in Amorim Tech Seal solutions is 100% natural and recyclable. By using cork in our solutions, we help reduce the environmental impact associated to rubber and, consequently, contribute to a better future.

For more detailed information and technical specifications, please book an appointment with our team so that we can analyse your project and recommend the best solution.

To select the best sealing material for a gas system its constituent factors must be considered, such as the type of gas, necessary compressibility, required sealing load or seal thickness.

Amorim Cork Composites is part of various working groups that aim to develop new industrial processes that will ensure the applicability and extensive provision of hydrogen solutions.

Amorim Cork Composites has begun to develop cork composite solutions catered to advances in the hydrogen sector, in particular related to electrolysers.