Amorim NRT Top Layer is a component of high density cork designed for direct and digital printing, allowing a customized design.

Amorim NRT Top Layer has a Negative Carbon Footprint.

Reinventing flooring components

We provide unique solutions that allow our clients to reduce the carbon footprint of their final floor

Our materials are manufactured with Amorim NRT - Noise Reduction Technology, which in addition to greater noise reduction, preserves all its characteristics over time.

Turn your phone to explore the solution

Interactive image

The use of a Amorim NRT inlay placed very close to the noise source dissipates energy transmitted by the foot when hitting the floor.

View ProductThe use of a Amorim NRT Pre-Attached Underlayment acts like the traditional underlay, preventing the transmission of mechanical energy through the slab.

View ProductFull experience in the flooring industry

Amorim Cork Composites is able to supply all the components of the floor, except the floor itself!

Our experience has led to the development of unique technical components for flooring industry – Noise Reduction Technology (NRT).

We are focusing on product innovation and has a reactive innovation capacity (adapting to market demands) but also a proactive innovation capacity (product development). The product innovation is facilitated for a personal relationship with the key industry players and for our presence in flooring associations, such as MMFA.

-

Double Belt Press (DBP) Technology

Our mission is to be a one stop shop for flooring manufactures where they can find innovative and added-value solutions with competitive price and compatible with their production process.

The vision in this segment is for Amorim Cork Composites to be associated with innovation, trust and uniqueness.

With the Double Belt Press (DBP) technology, we are able to produce high density rolls with a maximum width of 2,1 meters.

-

We have the capability to supply products specifically designed for the customer’s process

The flooring manufacturers have a most produced panel dimension for flooring because mainly they are also producing MDF/HDM or just because they are buying with a specific dimension.

The flooring manufacturers have high focus on operational efficiency and technological developments and, because of this, they require material suppliers that understand their industrial needs and how their materials (compatible with production process) will be applied and are aware of consumer trends begging innovation to correspond to the expectations.

One of our main advantages is to design sheets, panels or rolls accordingly, minimizing the impact on the process cost.

Focus on product innovation

-

-

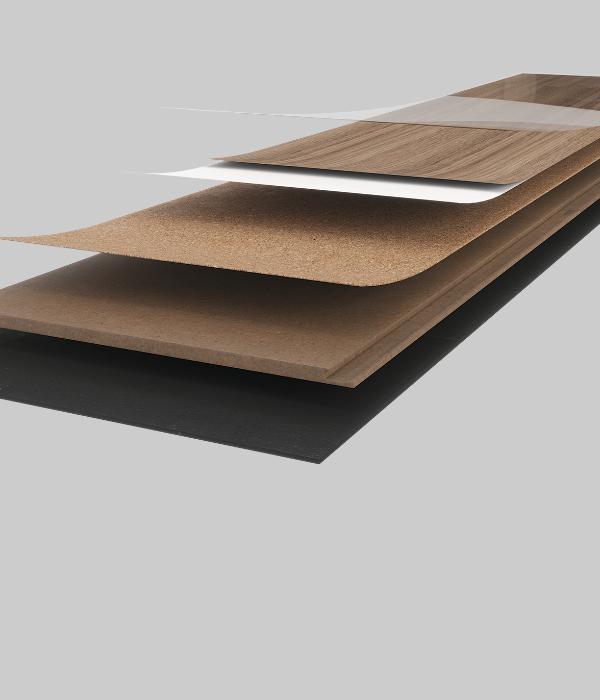

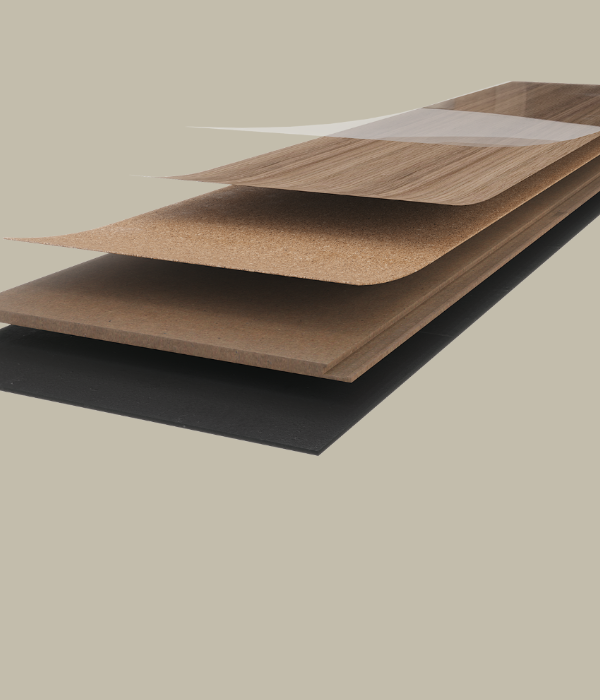

Top Layer

Printable surface that allows the freedom to design

-

-

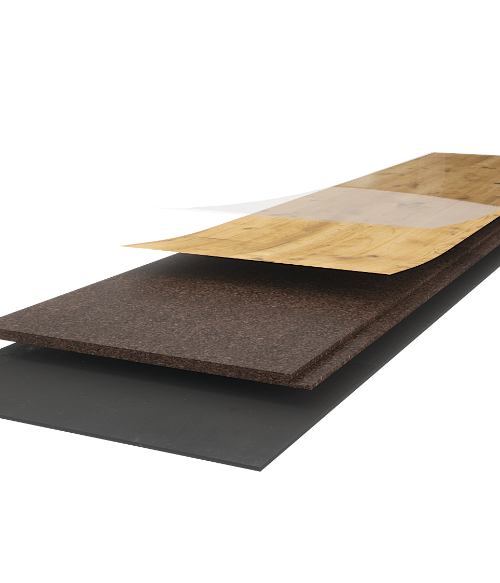

Inlay

Footfall Noise Insulation through a natural and thin layer

-

-

Core Layer

Dimension Stability through a cork compound

-

-

Pre-Attached Underlayment

Impact noise insulation as part of the system