A good sealing solution, regardless of the application, plays a crucial role in ensuring the safety, performance and durability of systems.

To select the best sealing material for a gas system its constituent factors must be considered, such as the type of gas, necessary compressibility, required sealing load or seal thickness.

-

But, what establishes a specific material as a good sealant?

A good sealant must essentially fulfil two functions: to join together and serve as a barrier.

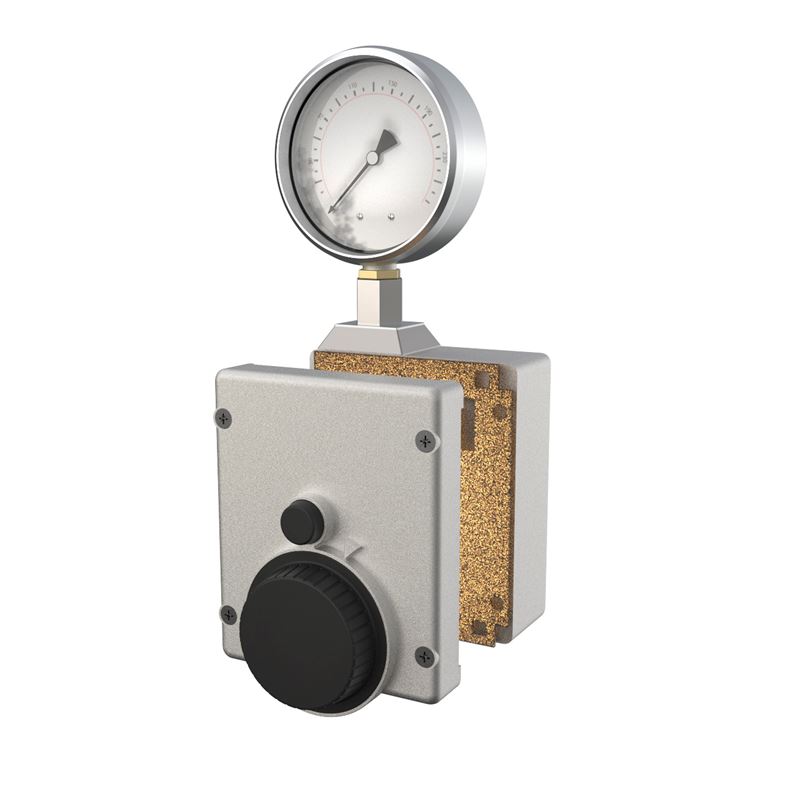

When applied to a flange, a sealant must prevent the passage of different types of gases or oils to other parts of the system, to guarantee its performance. In the case of gas systems, the choice of a good sealant becomes even more important since serious security breaches may otherwise arise.

All sealing solutions developed by Amorim Cork Composites observe a regulated set of approvals and certifications, in order to guarantee the quality of its materials.

Factors to consider when choosing a sealing material

When choosing a sealing material that guarantees good performance for a gas system over time, the following factors must be taken into account:

Type of gas

The type of gas circulating in the system is one of the main factors to be considered, since the seal will come into contact with it. Each gas has a unique set of characteristics that must be analysed to understand the effect it will have on the material. This analysis makes it possible to choose a material that is more resistant to the degradation that may result from contact with the gas (which can cause the appearance of failures or ruptures) and avoids contamination of both the gasket and the gas, thereby ensuring that the system’s performance is not undermined.

Temperature and pressure

In addition to isolating the application correctly, it is necessary to ensure that the material maintains its properties intact, when subjected to increases to the temperature and pressure during the system’s operation. Most materials have limitations in terms of resistance to temperature and pressure, so it is crucial to check the maximum values that can be attained.

Cork, the ideal material for gas sealing solutions

Cork’s thermal and chemical resistance and impermeability to liquids and gases make it the ideal raw material to develop sealing solutions. In addition to complying with the different technical specifications of gas systems, cork helps reduce the system's carbon footprint, which is essential in order to attain sustainability goals.

Using cork - a natural and sustainable material - we have combined Amorim Cork Composites' knowledge and experience in highly demanding industries, to create the Amorim Tech Seal range of sealing solutions.

Amorim Tech Seal solutions consist of cork and rubber composites that have been specifically developed to produce the most suitable sealing materials. The range’s principal benefits include load-to-seal for effective sealing (i.e. the screws used can be smaller, delivering greater stability to the system), controlled side flow and high tolerance to surfaces that reveal some distortion (good conformability).

Would you like to learn more about Amorim Tech Seal solutions? Contact our team now.

Would you like to know more about this subject?

Let us know your details and we'll get back to you.