"Cork. Don’t leave Earth without it!"

Interview to Donald Thomas, NASA astronaut.

Amorim TPS

Our Aerospace grade materials constituents and structure make them ideal thermal protection materials with excellent ablation and insulating properties, maintaining a low weight to low thermal conductivity performance, creating a sturdy char layer that protects the inner material, maintaining its integrity and slowing thermal degradation.

We’ve been part of several development programs for Aerospace grade ablative materials such as Aerofast and Ablamod, paving the future for next generation materials that are lighter and more efficient in thermal protection.

Tradition blends with technology in the heat of the rocket booster.

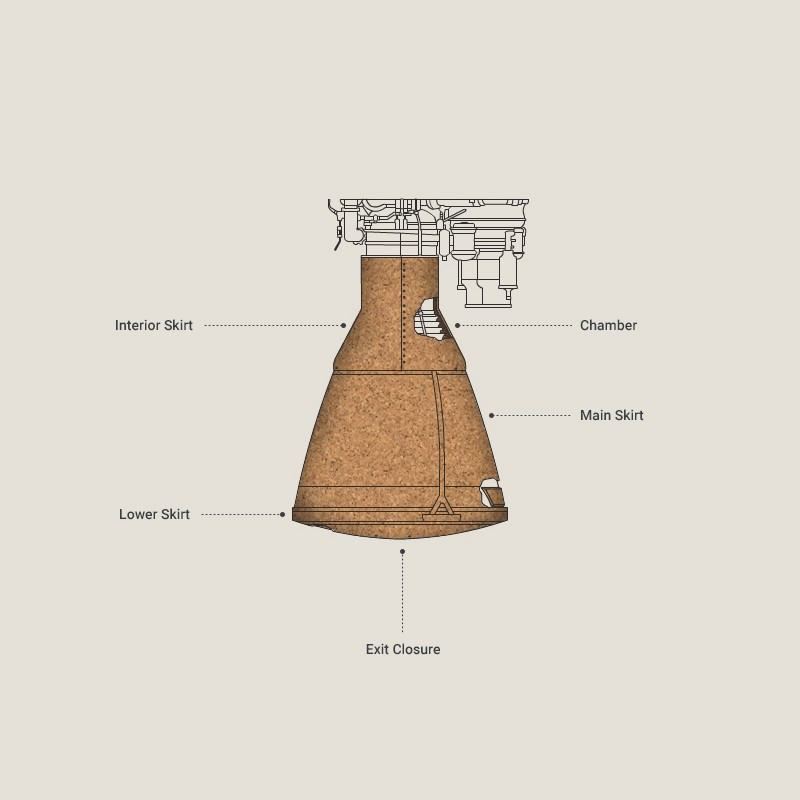

Our products are applied in SRB (solid rocket boosters) engine skirting, nose cone, frustum, forward and aft skirt, external tank attach ring covers, assembly and tunnel covers and range safety system crossover covers.

Besides SRB’s, we also develop solutions for payload fairings, space probes entry heat shields, impact protection for debris mitigation and internal thermal insulation of hot structures.

Our products can be easily bonded to most substrate materials, using designated adhesive systems and coated with specific coatings or varnishes. Parts can be trimmed and machined with tooling to the required geometry and also easily integrated into FRP (fiber reinforced plastics) structures.

The data provided in this table represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipments damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Composites expressly disclaims all warranties, including any implied warranties or merchantability or of fitness for a particular purpose. Amorim Cork Composites is not liable for any indirect special, incidental, consequential, or punitive damages as a result of using the information listed in this table. Any of its material specification sheets, its products or any future use or re-use of them by any person or entity.

Interview to Donald Thomas, NASA astronaut.

Ablative Thermal Protection System for IXV.

Amorim Cork Composites is going to hit aerospace again, this time with United Launch Alliance (ULA) and Ruag Space.