Ablative thermal solution P50 in next-generation launch rockets

Ablative thermal solution P50 in next-generation launch rockets

AEROSPACEAmorim Cork Composites is going to hit aerospace again, this time with United Launch Alliance (ULA) and Ruag Space.

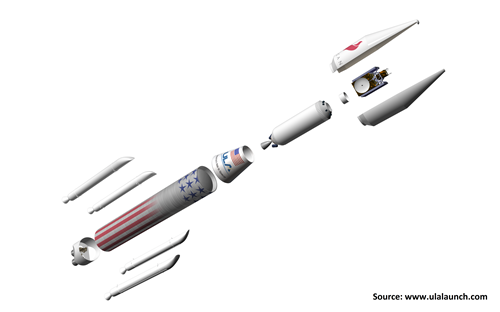

Next-generation launch rockets of ULA, using composite primary structures supplied by Ruag Space, are going to incorporate Amorim’s ablative thermal solution P50. Under the name Vulcan, these ULA launch rockets will replace Atlas and Delta Launchers, currently using Amorim's product.

Fairing shell with Amorim P50 ablative thermal solution

Composites World website provides the news and summarizes very well Amorim’s solution:

"The outer skin of the ogive section is laid up manually on a dummy mold. Thermal protection in the form of a compressed cork provided by Amorim Group (Mozelos VFR, Portugal), is positioned over the layup. The part is transferred to the bonding mold by means of hundreds of small vacuum pads arranged on another dedicated jig.

Lastly, a layer of the cork is arranged over the outer skin of the cylindrical section. The cork, bonded on the outside skin of the fairing’s composite sandwich protects the sandwich from the aerodynamic frictional heat generated on the fairing’s exterior. The complete part sandwich layup is now ready for vacuum bagging and cure.

Vulcan, ULA’s next generation launch system (NGLS)

Read the full article at: compositesworld.com.