A sustainable way to increase the performance of T&D applications

Cork solutions contribute to a more sustainable future and have been used for several years in industries such as aerospace, automotive or power industry..

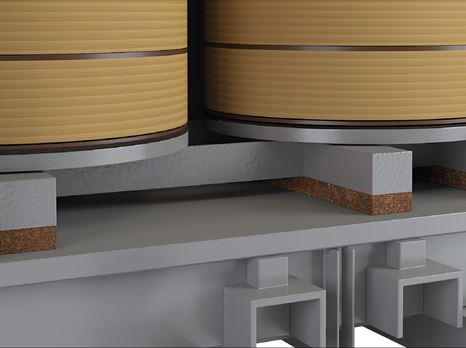

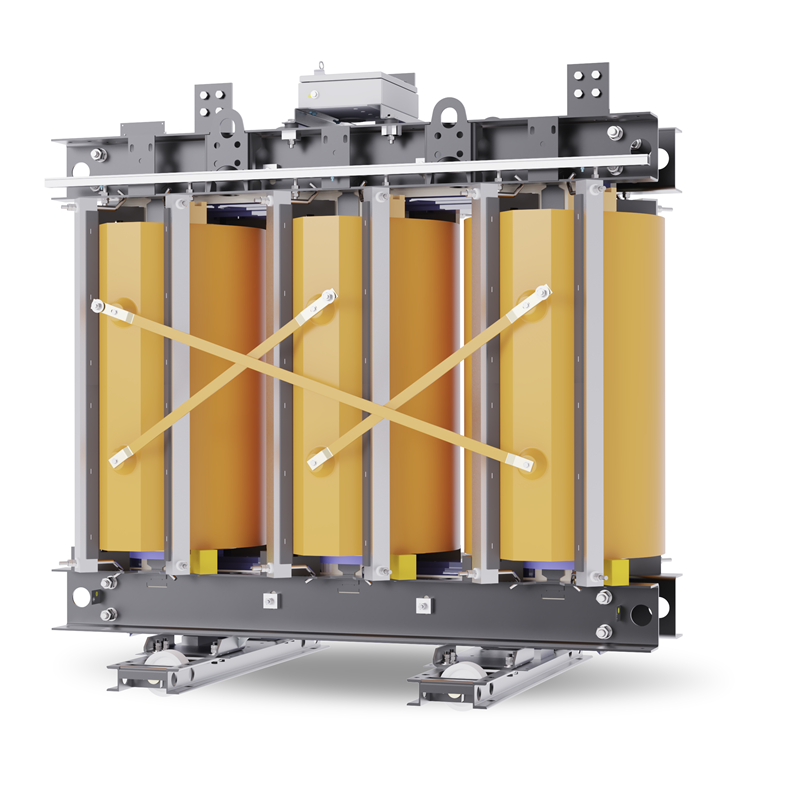

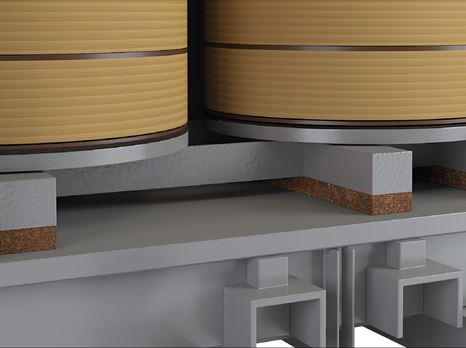

Noise and vibration control for dry transformers

However, greater vibration and noise control is required for any system intended for installation in residential areas. Amorim T&D's range of vibration control (VC) solutions can help mitigate this problem, while helping reduce wear and tear on the system's parts and its environmental impact.

Cork composites as a solution for vibration and noise control

To deal with the challenges associated with noise and vibration in dry-type transformers, the system can be optimised in various different ways - in terms of damping, acoustic insulation and increased energy dissipation. This makes it essential to choose the best materials for this purpose.

Amorim T&D cork composite solutions have been specially developed to meet such challenges. Due to its air-filled, cellular structure, cork has a natural resilience, which allows it to absorb vibrations and cushion mechanical shocks. When used in transformers, cork composite solutions can mitigate vibration transmission, reducing noise levels and minimising structural resonance. Furthermore, cork’s unique composition dampens vibrations, and thereby effectively attenuates the propagation of sound waves inside transformers, or their surroundings.

Allied to the high performance of Amorim T&D materials, Amorim Cork Composites has implemented a four-step approach in the analysis and treatment of noisy equipment, which focuses on the need to control vibrations prior to reaching the structure of the tank (and therefore closer to the vibration source). This approach ensures that structural vibrations in the tank are not transformed into airborne noise, through amplitude vibration of its walls acting as "loudspeakers".

The electrical industry's commitment to developing safer and more sustainable equipment delivers many benefits for people and the environment, but also leads to new challenges in terms of vibration and noise control.

Cork composite solutions offer various benefits to respond to these new challenges, since their natural resilience, flexibility and acoustic insulation make these solutions effective for damping vibrations, reducing noise levels and improving the system’s overall performance and working life. By using Amorim T&D solutions, manufacturers can optimise the designs of transformers to meet stringent noise and vibration requirements, creating quieter and more reliable electrical infrastructures for various applications. Amorim T&D solutions are also more sustainable materials (compared to 100% rubber solutions) and thereby contribute to greater sustainability of the system.

In addition to its technical advantages, cork is one of the world’s most versatile materials and is 100% natural. Studies show that for every tonne of cork produced, the cork oak forest sequesters up to 73 tonnes of CO2, and no trees are felled in the process.

Are you looking for sustainable solutions to mitigate the noise and vibration of your dry-type transformers? Contact us now!

Cork solutions contribute to a more sustainable future and have been used for several years in industries such as aerospace, automotive or power industry..

The Amorim T&D range of solutions are performance-driven and recognized worldwide, with a long track record of application in transformers, reactors, bushings, and other T&D components. But what makes our solutions so unique? The answer comes naturally: cork.

Benefits of cork in vibration and noise in electrical production and distribution networks