Case studies of the use of cork in T&D

Benefits of cork in vibration and noise in electrical production and distribution networks

How to extend the lifetime T&D components?

Amorim T&D solutions developed for the power industry are based on specific polymer formulations with cork. Cork is a 100 % natural, renewable and recyclable raw material whose characteristics include elasticity, vibration control, chemical resistance, shock absorption, flexibility, impermeability to liquids and thermal resistance

Our range of engineered sealing materials is based on soft gasket technology, specifically designed and tested to withstand stringent application needs in diverse environments while providing effective final product customization and manufacturing options.

The fact that cork has a closed cell structure, filled with air and primarily comprised of suberin and lignin, makes it a permeable material, suitable for contact with the main insulating oils used in this industry, such as mineral, ester (synthetic and natural) and silicone oils. One of the problems that arise when sealing this type of equipment is how to control the side flow of the material within the flange. The presence of cork in these solutions has a positive impact on the shape factor compared to rubbers. While rubbers are considered to be incompressible and require space to displace the compressed volume, the rubber-cork formula developed by Amorim Cork Composites displaces much less volume, due to the cork’s internal compression (lower Poisson ratio), allowing for a wider shape factor tolerance, which influences the overall robustness of the design.

Cork’s characteristics endow greater firmness and high conformability, ensuring good sealing ability, even in large contact areas. Additionally, cork composite solutions also adapt very easily to imperfect surfaces, regardless of the contact area and the compression exerted.

Power transformers are often installed near residential areas, where strict noise requirements have been introduced. This has intensified the need to produce equipment that not only guarantees good long-term performance but also achieves greater vibration control and consequent noise reduction. It is often said that “just putting some rubber” to isolate structures creates an inefficient or even a vibration isolation problem. This occurs because the characteristics of the overall system are not considered. Various characteristics - such as the environment and temperature, material stiffness adjusted to the application load, surface area, material’s transmissibility, pad design techniques, and shape factor conformity - must be considered before choosing an anti-vibration material to achieve all the

required results.

Through our experience in T&D applications, Amorim Cork Composites has implemented a 4-step system approach in the analysis and treatment of “noisy” equipment. This approach focuses on the need to control vibration before it reaches the tank structure (i.e. intervening closer to the source of the vibration), thereby ensuring that structural vibration on the tank isn’t transformed into airborne noise through the amplitude vibration of the tank walls, acting as “loudspeakers”.

Firstly, we use internal vibration pads inside the transformer underneath the active part. Secondly, we look at the connections between the active part and the tank, to the combination of metal-to-metal connections. Thirdly, we can use a CLD (Compressed Layer Damper) inside the tank wall. Finally, we can apply external vibration pads outside the transformer. This approach can be adjusted to the customer’s final hardware design and any corresponding limitations.

Cork’s closed cell structure contributes to the damping function by dissipating vibration energy when compared to 100 % rubber materials. This dissipation of vibration energy leads to noise reduction, longer machine or tooling life and minimal transmission to the surroundings.

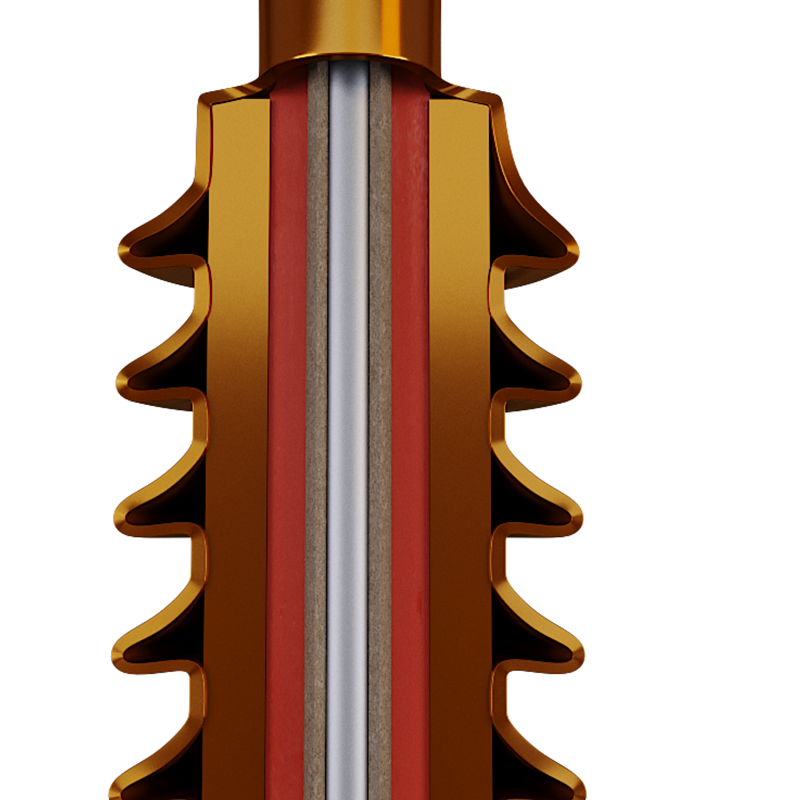

Amorim T&D solutions are being used by RIP Bushing manufacturers due to their unique characteristics. Due to cork’s characteristics - in particular, the compression and recovery features – our solutions serve as excellent stress/dimensional absorbers during the resin impregnation process, accounting for compression due to resin shrinkage (curing process), preventing cracking of the resin insulator. The ability to absorb expansions and contractions ensures a strong performance of our solutions throughout the life cycle of the RIP insulator.

In addition, the dielectric characteristics and low poison coefficient of cork-rubber solutions improve the RIP bushings’ electrical loss and prevent the creation of

internal stresses and extrusion.

For more information, visit https://amorimcorkcomposites.com/en/our-brands/amorim-td/.