New materials, new processes, more circular economy

New materials, new processes, more circular economy

Based on the motto that “nothing is wasted, everything is valued”, the principles of the circular economy have been applied at Amorim Cork Composites from the outset, given that the company was born with the purpose of giving new life to any waste cork resulting from the production of cork stoppers.

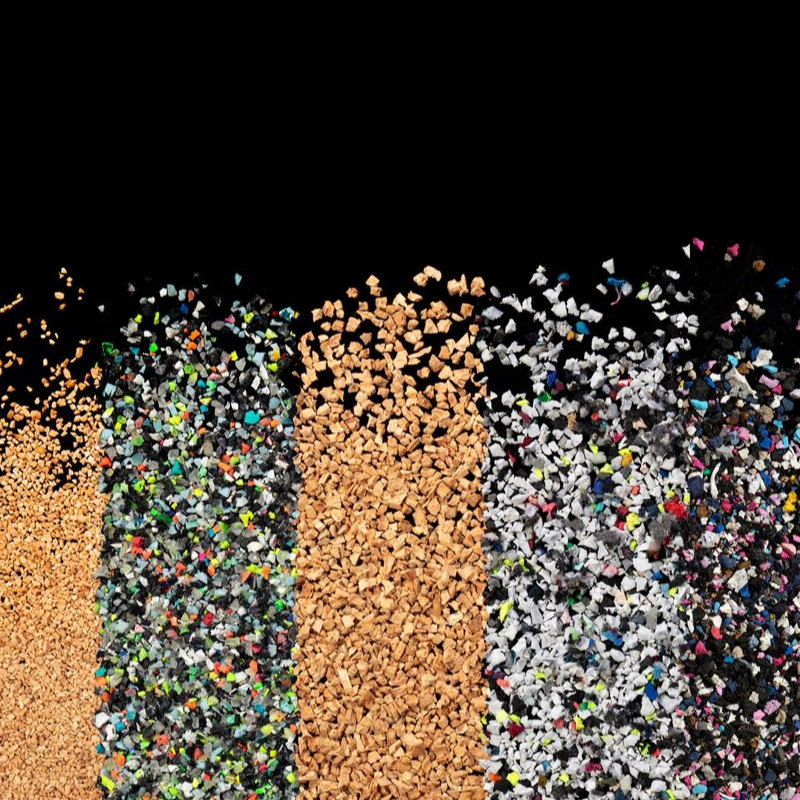

In order to reinforce this proposal of ecological value based on a model of circularity, new product ranges are being updated, incorporating surplus raw materials from other industries, such as footwear, automobile, sports or upholstery production, whose final destination would otherwise have been landfilled. These materials are used to develop new cork composites, in line with the responsibility of reusing and saving natural resources and helping generate added value for the business.

-

New products and new tendencies

Incorporation of non-cork raw materials, and thereby promoting industrial symbioses with other companies, enables us to create new products and new trends, increasing the company's competitiveness, and generating differentiation that maintains cork as an essential and distinctive raw material.

This is a new strategy, based on investment in new areas and new technological processes. One example is the creation of the i.cork factory, a pilot innovation factory, plus a major commitment to the procurement of raw materials and the installation of new shredding and agglomeration lines.

At i.cork factory, opportunities for incorporating materials from the circular economy are explored on a daily basis.

The unit’s main mission is to design new materials that will continuously respond to the needs of the different business areas in which it operates, and also test and explore the application of technologies that haven’t yet been industrialized in the sector.

Procurement of raw materials has increased our network of suppliers, ensuring constant supply in function of market needs. In operation since late 2018, the new shredding line now makes it possible to shred low-density foams and increases the shredding capacity of raw materials that were already being shredded, such as PUR and EVA.

-

At the forefront in creating value from recycled materials

The new agglomeration line, expected to commence operation in 2019, is mainly focused on the production of cork composites mixed with raw materials from the circular economy, such as PUR and EVA, among others.

In line with current market trends, Amorim Cork Composites aims to be at the forefront in creating value from recycled materials, innovating in terms of products, process and marketing. This is expected to leverage Amorim Cork Composites' resources, expertise and production processes, consciously and responsibly managing the valuable raw material of cork.

Eduardo Soares, Innovation Director, Amorim Cork Composites

João Queirós, Raw Material Procurement Officer