STC refers to the measurement used to quantify the transmission of airborne sound through building elements, such as walls or floors. This type of noise would be the equivalent of voices, music, or similar. STC translates to Sound Transmission Class and it is measured and tested per ASTM Test Method E90.

Simplify the sound control for flooring applications in multi-family construction

How to simplify the sound control for flooring applications in multi-family construction

Larry LyonsDifferent types of assemblies and flooring have different needs and there is no single product that is appropriate for all types of flooring.

To make an intelligent decision about what type of product to specify or install, it is important to understand what is required by the Building Code and what the performance standards of STC and IIC actually mean.

In multi-family construction in the United States, there are minimum IIC and STC values that a floor/ceiling assembly (living space over living space) must achieve. The Uniform or International Building Code (U.B.C. / I.B.C.) call for a minimum 50 IIC and 50 STC values. It is important to consult the local Building Department, Homeowners Association or Property Manager for the exact requirements for your installation.

Sound Control Underlayments and the Flooring products installed contribute almost nothing to the STC rating of a flooring assembly. The mass of the structure is what contributes to the STC value. A 6” solid concrete slab, for example, has an STC rating of about 52. STC ratings in the 60’s or 70’s on Sound Control Underlayment product data sheets indicate that a ceiling assembly was used in the testing and the ratings noted should be viewed with skepticism.

IIC refers to the measurement used to quantify the transmission of impact sound through a flooring assembly. IIC sound is the equivalent of footsteps, dropped articles, or furniture being dragged across the floor. IIC means Impact Isolation Class and it is measured and tested for per ASTM Test Method E492. There is an additional IIC test standard for concrete subfloors defined by ASTM Standard E2179. This standard states the IIC rating as the Δ (Delta), or contributed value for the underlayment and flooring and is meant to provide some clarity as to the actual performance of systems. If you are looking at Δ IIC data, in most cases a Δ IIC value higher than 20 will be required to provide Code Compliance.

There is also a Field Test method for IIC testing (ASTM E1007). Tests done using this method are called FIIC tests. Products that have only FIIC data should be considered with caution. Field is very location-specific, because of the wide variety of variables that can be encountered. Comparing the FIIC data of one product to the lab IIC testing of another product is not an accurate way to make an assessment of relative performance.

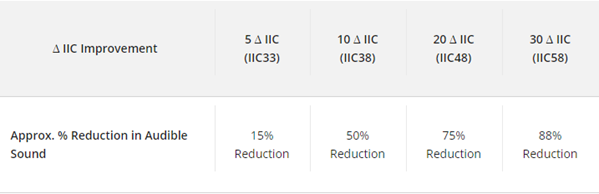

IIC values are not heavily influenced by the presence of mass in the structure. A 6” solid concrete slab, for example, has an IIC rating of about 28, without underlayment or flooring materials installed. Wood frame assemblies, without a sound mat or flooring installed typically have IIC ratings around 30. These ratings are well below the Building Code requirement of 50 IIC and the addition of hard surface or vinyl flooring without an underlayment will not markedly improve the IIC rating. IIC improvement requires a resilient material somewhere in the assembly to isolate and absorb the sound energy created by impacts. The table below shows the IIC for a 6” concrete slab at various levels of ∆ IIC improvement and what the approximate % reduction in audible sound would be.

IIC Improvement

| ∆ IIC Improvement | 5 ∆ IIC (IIC33) | 10 ∆ IIC (IIC38) | 20 ∆ IIC (IIC48) | 30 ∆ IIC (IIC58) |

|---|---|---|---|---|

| Approx. % Reduction in Audible Sound | 15% Reduction | 50% Reduction | 75% Reduction | 88% Reduction |

To attenuate IIC noise in floor assemblies, a Resilient or Sound Control Underlayment is required. The correct Underlayment will provide the resilience required for code complaint IIC noise reduction and the structural stability required for a responsible flooring installation. Floating hardwood or laminate flooring are typically the least and bonded ceramic tile or natural stone assemblies are the most challenging application for sound attenuation performance. Vinyl products (aka LVT), are used extensively in lieu of carpet today in multi-family housing and present their own challenges. With vinyl products, there is a limit to the thickness of sound control products that can be used to prevent issues with indentation of the flooring.

Different types of assemblies and flooring have different needs and there is no single product that is appropriate for all types of flooring. That is why the market offer a number of different products. Look for a manufacturer who can supply acoustical testing data that most closely matches the type of flooring and the construction of the building the products will be installed in.

If a Sound Rated Ceiling Assembly was used in the testing, it should be disclosed and described in the test report. You should be able to see the test report and not just rely on the result shown on the product data sheet. If a potential supplier does not have a tested assembly that closely approximates your conditions, you may be better served finding a supplier who does.

You should make sure the underlayment product will be compatible with the flooring product selected and that the installation will produce a Code Compliant result.