Vibration Control and Compressed Layer Damping

Noise reduction in transformers & reactors through decoupling and isolation.

Power Equipment and Accessories Seals and Gaskets

Unique blends of cork and select rubbers produce materials indicated for flat sealing applications, that due to reduced side flow, allow for larger contact areas and higher compression ratios which guarantee an effective sealing barrier against potential flange surface imperfections, distortions and leakage paths.

Extensive material testing and application evaluation continues to drive the development of unique materials and solutions in this product family, while maintaining its recognition and track record with a long history in transformers, reactors, bushings and other T&D components.

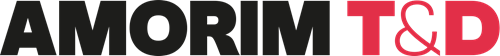

Test protocols based on similar industry long term validation tests performed on gasket materials TD1120 & TD1049 under flange compression and in full contact with mineral insulation oil, subject to a severe ageing cycle (over 1500h at 167ºC) equivalent to over 30 years of service life. Results have shown minor change to materials properties, confirming the experience of Amorim T&D products in the power industry.

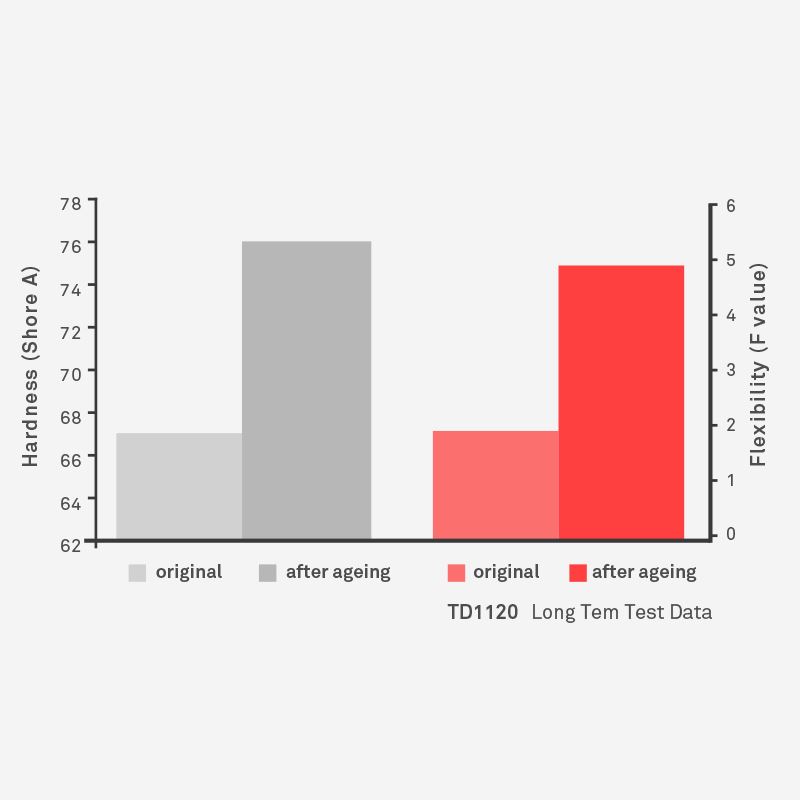

Amorim TD1310 Nitrile cork-rubber blend is formulated for low temperature sealing, showing compliance to a minimum of -55ºC, according to ASTM material testing procedures such as temperature retraction testing and DMTA glass transition methods. Application thermal cycling down to -60ºC has confirmed why several OEM’s are making it their choice sealing material for equipment working in close to Artic conditions.

Cork Rubber Sealing

| Grades | TD1049 | TD1120 | TD1310 | TD7000 |

|---|---|---|---|---|

| Low temperature resistance (°C) | -30 | -40 | -50 | -60 |

| High temperature resistance (°C) | 125 | 125 | 110 | 175 |

| Mineral Oil | ++ | ++ | ++ | + |

| Silicone Oil | ++ | ++ | ++ | |

| Ester Oil | ++ | ++ | ++ | + |

| SF Gas | + | + | + | |

| Typical values: + Acceptable ++ Suitable | ||||

The data provided in this table represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipments damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Composites expressly disclaims all warranties, including any implied warranties or merchantability or of fitness for a particular purpose. Amorim Cork Composites is not liable for any indirect special, incidental, consequential, or punitive damages as a result of using the information listed in this table. Any of its material specification sheets, its products or any future use or re-use of them by any person or entity.