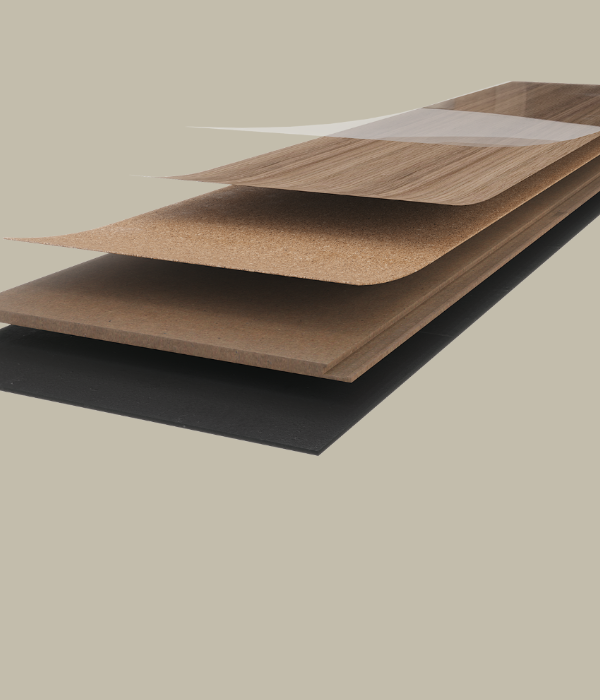

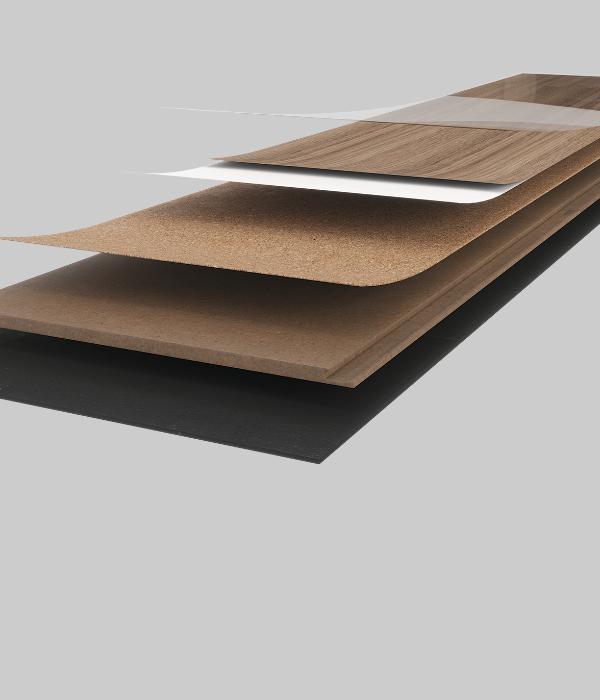

Pre-Attached Underlayment

Soft touch and silence thanks to cork.Impact noise insulation as part of the system.

The use of a NRT pre-attached underlayment acts like the traditional underlay, preventing the transmission of mechanical energy through the slab. The perfect energy attenuation is provided by the engineered combination of different cork granules, targeted to be underneath the MDF, plywood, staves, WPC's or polymer, or polymer-composite substrate.

A pre-attached underlayment cork layer on the reverse dulls impact noise and improves the laying characteristics of the flooring.

-

Build a final flooring thinking about customers feelings

Cork’s normal temperature is very close to the human body, it therefore feels warm to the touch and the cork surface transmits a smooth touch.

As pre-attached underlayment, agglomerated cork is perceived since the first interaction with the floor and it is arousing positive feelings that are associated to cork.

However, cork is not only a marketing tool, in fact cork brings technical benefits and when used as pre-attached underlayment it is the excellent option to improve impact noise reduction and a way to provide differentiation through a natural material.

-

A kraft paper carrier for the pre-attached underlayment

A paper kraft carrier is available to laminate to the cork backing, improving the tensile strength, the client’s production process efficiency and the final floor value proposition. This sustainable and natural solution will improve the homogeneity of the adhesion of the pre-attached underlayment to other layers of the floor.

Key features

“For us, cork is a very important aspect of the business. We have produced cork floors for 29 years and we have a strong relation with this natural product and its evolution. Cork is very important since it differentiates us from other producers. We place a priority on cork in our innovation processes. When we think about a new product, we explore how cork can help its development.”

Would you like to know more about this subject?

Let us know your details and we'll get back to you.

Technical Specifications

| Units | NRT 49 | NRT 45 | NRT 62 | |

|---|---|---|---|---|

| Density | (kg/m³) | 200 - 270 (12.5 - 17 ib/ft3) |

150 - 210 (9.4 - 13 ib/ft3) |

360 - 450 (22.5 - 28 ib/ft3) |

| Compressibility at 0,7 MPa (100 psi) | % | 15 - 35 | 30 - 50 | 10 -30 |

| Recovery at 0,7 MPa (100 psi) | % | ≥ 70 | ≥ 70 | ≥ 70 |

| Tensile Strenght | kPa | ≥ 200 (> 29 psi) |

≥ 300 (> 43.5 psi) |

≥ 600 (> 87 psi) |

| Availability | - | Rolls & Sheets | ||

| Width (minimum - maximum) | mm | 100 - 1250 (4 -49 in) |

100 - 1250 (4 - 49 in) |

100-2100 (4 - 83 in) |

| Length (minimum - maximum) | mm | sheets: 600 - 3000 (24 - 118 in) rolls: 600 (24 in) - equivalent ∅1000 (39 in) |

sheets: 600 - 3000 (24 - 118 in) rolls: 600 (24 in) - equivalent ∅1000 (39 in) |

sheets: 600 - 3000 (24 - 118 in) rolls: 600 (24 in) - equivalent ∅1200 (47 in) |

| Thickness (minimum - maximum) | mm | 0,8 - 8 (0,03 - 0,3 in) |

0,8 - 8 (0,03 - 0,3 in) |

0,8 - 8 (0,03 - 0,3 in) |

| Finish | - | NA | NA | Calibrated 1 side |

The data provided in this table represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipments damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Composites expressly disclaims all warranties, including any implied warranties or merchantability or of fitness for a particular purpose. Amorim Cork Composites is not liable for any indirect special, incidental, consequential, or punitive damages as a result of using the information listed in this table. Any of its material specification sheets, its products or any future use or re-use of them by any person or entity.

-

-

Top Layer

Printable surface that allows the freedom to design

-

-

Inlay

Footfall Noise Insulation through a natural and thin layer