Power Equipment and Accessories Seals and Gaskets

Performance-driven and recognized worldwide.

Vibration Control and Compressed Layer Damping

Cork plays a significant role in the elastomer and is directly responsible for the damping function, commonly designated as the energy loss factor, while the rubber matrix takes care of the isolation, together they are the ideal combination when considering vibration and noise reduction solutions especially at resonance frequencies.

The elastomeric blend is distinctive to rubbers which are incompressible, needing space to displace the compressed volume, cork rubber displaces much less volume due to corks compression within itself allowing for a wider tolerance in part shape and dimensions commonly designated as the shape factor, which in turn affects the design robustness.

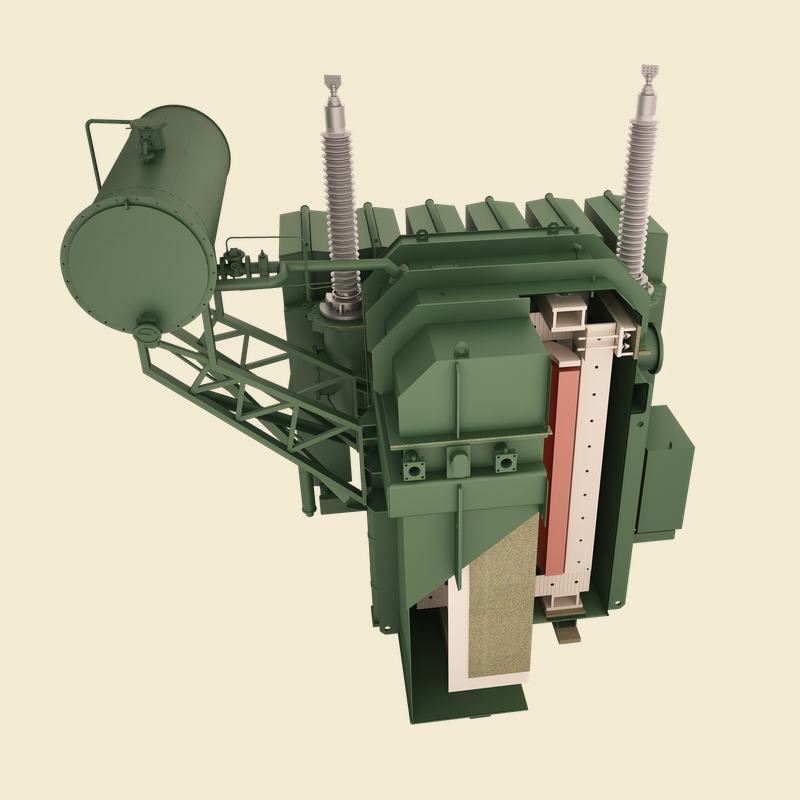

Amorim VC2100 vibration control material is especially used in power transformers and reactors as vibration pads beneath the active part immersed in oil, as well as decoupling supports between the core structure and the tank wall or tank cover on the core clamping mechanism. It can also be implemented for structural damping between the tank/shunt wall interfaces as a compressed layer damper. VC2100 appropriately applied is able to reduce up to 6dB in overall transformer noise.

A number of different options are available to the power industry for external vibration pad materials. The VC6400 power grade formulated for longevity in outdoor environments and designed to withstand conditions such as the presence of Ozone/UV.

| Grade | VC2100 | VC1047 | VC6400 |

|---|---|---|---|

| Max. Load | 2.0 MPa | 1.5 MPa | 2.0 MPa |

| Work Load Range | 0.5-1.5 MPa | 0.25-1.0 MPa | 0.5-1.5 MPa |

| Temperature Range | -40°C to 125°C | -25°C to 120°C | -50°C to 110°C |

| Creep rate * | < 2.0% | 1.7 % | 1.4 % |

| Application | Oil Immersed Vibration Control | External Vibration Control | External Vibration Control |

* Tested according to ISO8013 above their load working conditions

The data provided in this table represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipments damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Composites expressly disclaims all warranties, including any implied warranties or merchantability or of fitness for a particular purpose. Amorim Cork Composites is not liable for any indirect special, incidental, consequential, or punitive damages as a result of using the information listed in this tabl. Any of its material specification sheets, its products or any future use or re-use of them by any person or entity.

Performance-driven and recognized worldwide.

Reduced vibration flanking through rigid fastener connections.

Crack prevention in resin impregnated bushings.