Heavy Duty

Heavy Duty

Case study

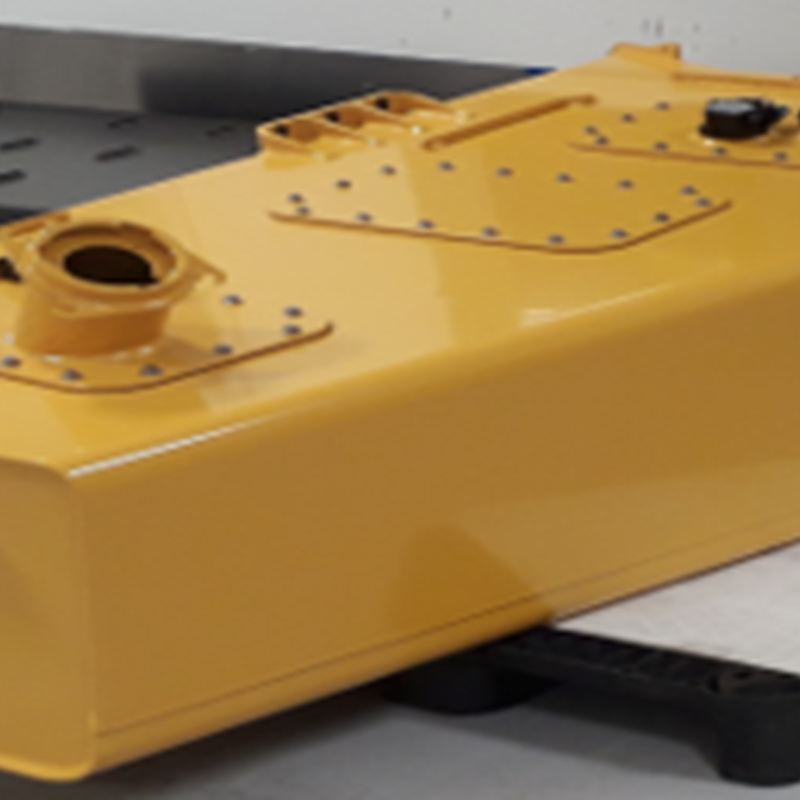

Development of gaskets for heavy machinery fuel tank capspesada

-

Cork and rubber gaskets

National is a Swedish partner company of Amorim Cork Composites for sealing solutions focused on the automotive industry. As it specialises in heavy machinery, selected Amorim Tech Seal solutions to seal the fuel tank caps of tractors, trucks, and other heavy vehicles.

The rubber-applied cork gaskets fully matched the customer's requirements in terms of performance, durability, and quality. Presenting high mechanical, thermal and chemical resistance to the various types of fuels and bio diesel (FAME - Fatty Acid Methyl Ester) used in different regions of the world, where vehicles are commercialised.

-

Performance and sustainability

In addition to the performance of Amorim Tech Seal products, the choice of a solution based on cork and rubber was also motivated by the fact that cork is a natural and sustainable material.

The sector has been increasingly focused on the end-of-life impact of vehicles, looking for materials that can be recycled and contribute to a circular economy, such as cork or the NRB composite, present in several references in the range.

Amorim Tech Seal Product range

| Material | Material description | Density (kg/m³) (lb/ft³) |

Hardness (pts) Shore A |

Compressibility % (400 psi) |

Traction resistance (MPa/psl) |

Temperature range (ºC/ºF) |

|---|---|---|---|---|---|---|

| TS2050 (D205) | Cork/SBR blend. Suitable for all engine and gear oils, and coolants. | 830* 52* |

60-80 | 15-35 | 2* 290 |

-30ºC a 90ºC -22°F to 194°F |

| TS4600 (GT46) | Cork/SBR blend. Suitable for all engine and gear oils. | >640 >40 |

70* | 25-45 | >1,03* >149 |

-30ºC a 110ºC -22°F to 230°F |

| TS1521 | Cork/SBR blend. Suitable for most lubrificant fluids. | 550-750 34-47 |

50-70 | 35-50 | >0,8 >116 |

-30ºC a 110ºC -22°F to 254°F |

| TS1400 | Cork/NBR blend. Suitable for fuels, bio-fuels, oils and coolants. | 1100* 68* |

75-90 | 10-22 | >3,5 >507 |

-30ºC a 125ºC -22°F to 254°F |

| TS7100(1) | Cork/NBR blend. Suitable for fuels, bio-fuels, and oils. | 900* 56* |

60-75 | 20-45 | 2,5* 362* |

-30ºC a 110ºC -22°F to 230°F |

| TS7111 (NC711)(1) | Cork/NBR blend. Suitable for all engine and gear oils, and coolants. | 800-960 50-60 |

70-85 | 10-25 | >2 >290 |

-30ºC a 110ºC -22°F to 230°F |

| TS7000 | Cork/Silicone blend. Suitable for coolants, and acceptable to most lubrificants. Used for very high and low temperatures. | 1100* 69* |

65-80 | 10-30 | >1,7 >249 |

-60ºC a 175ºC -76°F to 347°F |

| A099 | Cork/Silicone blend for injection molding. Suitable for coolants, and acceptable to most lubrificants. Used for very high and low temperatures. |

Depending on the injection process** | 63-73 | 10-30* | >3 | -60ºC a 175ºC -76ºF to 347º F |

| TS7610 (NL76) | Cork/Polychloroprene foamed blend. Suitable for all engine and gear oils, and coolants. | 470-620 29-39 |

30-50 | 30-45 (@100psi) |

>0,5 >72 |

-20ºC a 110ºC -4°F to 230°F |

| TS2030 | Cork/Polychloroprene blend. Suitable for all engine and gear oils, and coolants. |

750-850 47-53 |

60-80 | 25-40 | >1,96 >284 |

-40ºC a 110ºC -40°F to 230°F |

| TS7110 (711G)(1) | Cork/Epichlorohydrin (ECO) rubber blend. Exceptionally suitable for fuels, bio-fuels, oils and coolants. | 1100* 69* |

70-85 | 15-30 | 4,5* 653* |

-35°C / 135°C -31°F / 275°F |

*Typical value

Certifications and Approvals:

(1) UL157 Listed · Gaskets and Seals - requirements cover test procedures and performance criteria for the evaluation of nonmetallic gasket and seal materials for specific end products.

The data provided in these tables represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipments damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Composites expressly disclaims all warranties, including any implied warranties or merchantability or of fitness for a particular purpose. Amorim Cork Composites is not liable for any indirect special, incidental, consequential, or punitive damages as a result of using the information listed in this table. Any of its material specification sheets, its products or any future use or re-use of them by any person or entity.