Gas

Gas

Case study

Sealing solutions for gas equipment

Gaskets are a key element when it comes to ensuring the safety, performance and durability of a gas system. Each application has different requirements depending on the type of gas, required compressibility, required sealing load, seal thickness, among others.

-

Amorim Cork Composites has been supplying high quality sealing gas materials for over 25 years to various national and international customers.

In addition to cork and rubber seals for natural gas and LPG systems, we are expanding our product range by offering solutions for hydrogen. This and other low-carbon gases represent a decisive step towards the decarbonization goals of various sectors of activity.

Proven experience in gas meters and regulators

Alongside the development of new materials and solutions for the gas industry, we continue to offer quality solutions for the gas meters and regulators market.

-

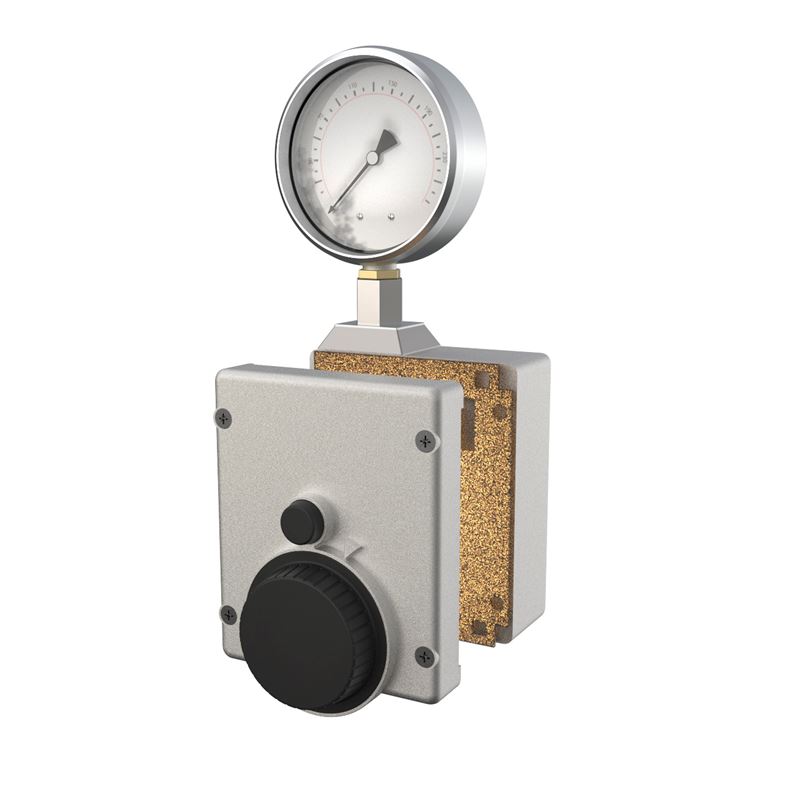

Gas regulators

Different hardware designs can be found in these applications, the regulator typically must comply to IP54.The regulator body is usually made from cast aluminum or from extruded aluminum profile sawed to specified thickness. The cast body can have a flat surface or have beads for additional sealing stress or even compression stops.

Due to design (stress beads and concentrated stresses below small bolts), crush-out and extrusion are potential failure modes where cork rubber sealing materials can truly benefit the sealing system.

-

Gas meters

These applications due to being situated outdoors are normally painted, adding another variability factor to the system. Other designs sometimes use a stress riser introducing the need for superior material resistance to crush-out. Therefore a great variety of flange loads are possible, depending on meter size, hardware distortion, flange area, and flatness (typically 200 to 1500 PSI)

Cork Rubber sealing materials typically perform well due to their great capacity to conform to different surface finishes and “absorb” the system distortion introduced by cast manufactured parts.

Amorim Tech Seal product range

| Material | Material Description | Density (kg/m³) (lb/ft³) |

Hardness (pts) Shore A |

Compressibility % (400 psi) |

Tensile strength (Mpa/psi) | Temperature range (ºC/ºF) |

|---|---|---|---|---|---|---|

| TS5500 (CR55R) | Cork/SBR & NBR blend, suitable for natural gas and LPG applications. | 560-800 35-50 |

55-70 | 30-50 | >1.03 >149 |

Up to 90ºC Up to 194ºF |

| TS1028 (1)(2)(3) |

Cork/NBR blend, suitable for natural gas and LPG applications. DVGW Approved. | 700-900 43-56 |

65-75 | 25-40 | >1 >145 |

Up to 125ºC Up 257ºF |

| TS7090 (2)(4) |

Cork/NBR blend, suitable for natural gas and LPG applications. JIA Compliant. | 650* 41* |

50-70 | 30-50 | 2* 290* |

Up to 110ºC Up to 230ºF |

*Typical value

Certifications and Approvals:

(1) DVGW Approved · Rubber/Cork and rubber/cork synthetic fiber based gasket materials for use with gas valves, gas appliances and gas pipe work.

(2) NP4464 Compliant · Cork/Rubber materials for tightness joints used in gas appliances, valves, devices and gas installation.

(3) EN 30.1.1, part 6.1.1.2 Compliant · Domestic Cooking Appliances Burning Gas, Durability of Sealing Materials.

(4) JIA C001 Compliant · Japanese gas appliance inspection association

The data provided in this table represents typical values. This information is not intended to be used as a purchasing specification and does not imply suitability for use in a specific application. Failure to select the proper product may result in either equipments damage or personal injury. Please contact us regarding specific application recommendations. Amorim Cork Composites expressly disclaims all warranties, including any implied warranties or merchantability or of fitness for a particular purpose. Amorim Cork Composites is not liable for any indirect special, incidental, consequential, or punitive damages as a result of using the information listed in this table. Any of its material specification sheets, its products or any future use or re-use of them by any person or entity.