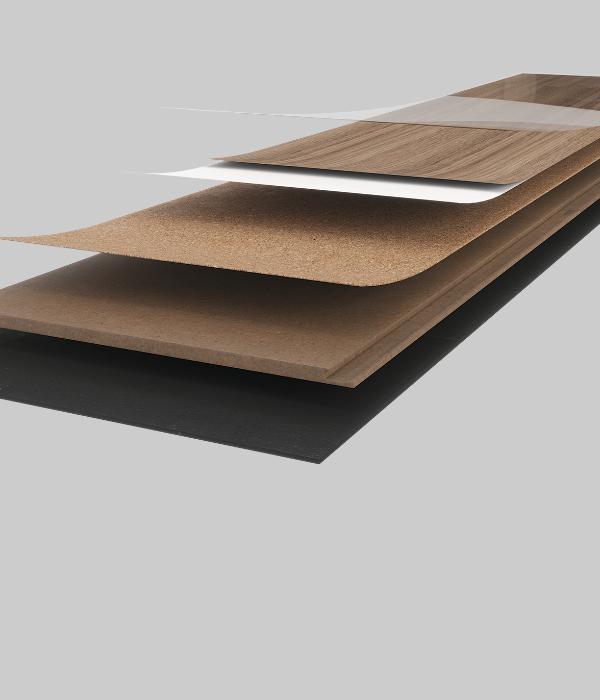

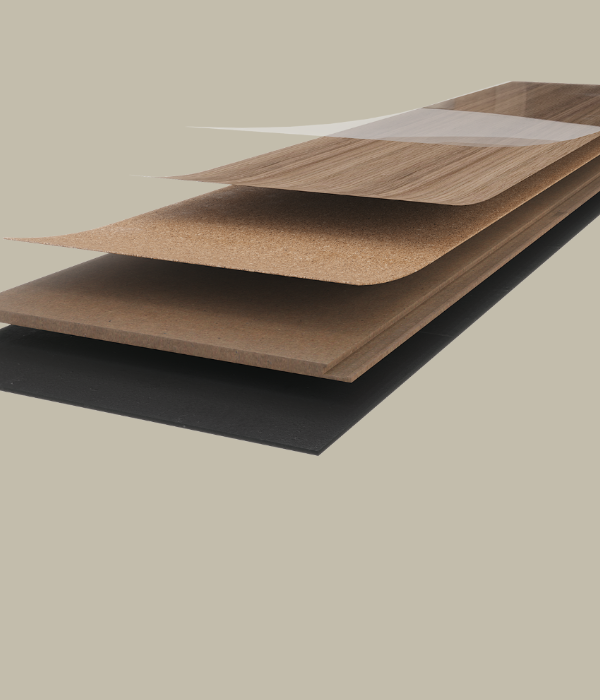

Amorim NRT Top Layer is a component of high density cork designed for direct and digital printing, allowing a customized design.

Amorim NRT Top Layer has a Negative Carbon Footprint.

Full experience in the flooring industry

We provide unique solutions that allow our clients to reduce the carbon footprint of their final floor

Our materials are manufactured with NRT - Noise Reduction Technology, which in addition to greater noise reduction, preserves all its characteristics over time.

Turn your phone to explore the solution

Interactive image

The use of a Amorim NRT inlay placed very close to the noise source dissipates energy transmitted by the foot when hitting the floor.

NRT Inlay - View ProductThe use of a Amorim NRT Pre-Attached Underlayment acts like the traditional underlay, preventing the transmission of mechanical energy through the slab.

NRT Pre-Attached Underlayment - View ProductInnovative solutions fulfilling the market requirements

Amorim Cork Composites is able to supply all the components of the floor, except the floor itself!

Our experience has led to the development of unique technical components for flooring industry – Noise Reduction Technology (NRT).

We are focusing on product innovation and has a reactive innovation capacity (adapting to market demands) but also a proactive innovation capacity (product development). The product innovation is facilitated for a personal relationship with the key industry players and for our presence in flooring associations, such as MMFA.

-

-

Top Layer

Printable surface that allows the freedom to design

-

-

Inlay

Footfall Noise Insulation through a natural and thin layer

-

-

Pre-Attached Underlayment

Impact noise insulation as part of the system