Application of cork to control vibrations and noise in T&D

Use of cork to control vibration and noise in power and distribution transformers

Case studies on the benefits of cork in electrical production and distribution networksPower transformers are often installed near residential areas, where strict noise requirements have been introduced. This has intensified the need to produce equipment that not only guarantees good long-term performance, but also achieves greater vibration control and consequent noise reduction.

It is common to associate the use of materials composed entirely of rubber to guarantee this vibration control, however, the use of such materials can cause several problems in their application and in terms of vibration isolation.

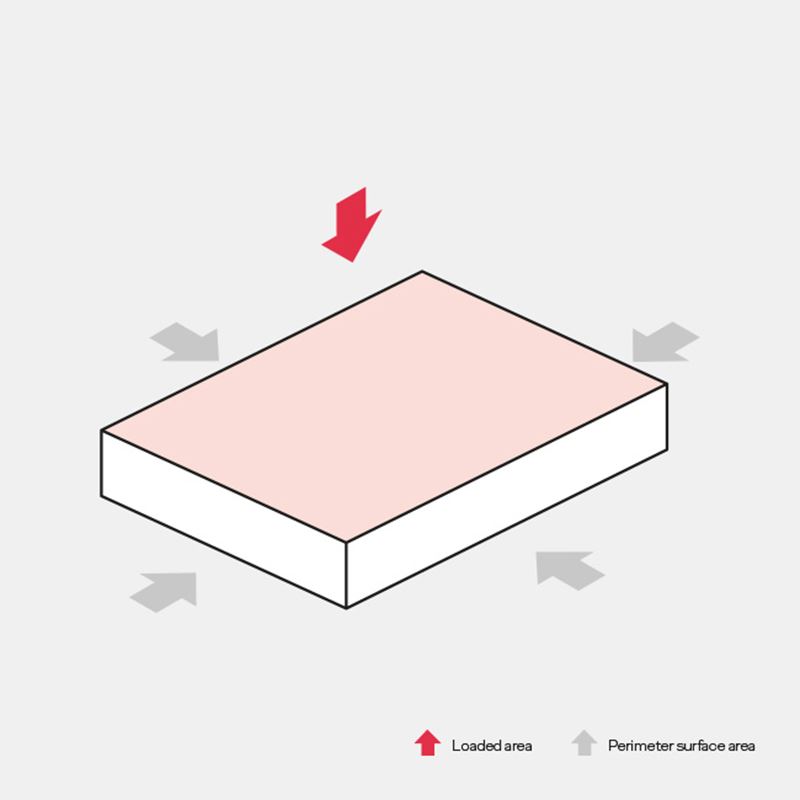

This occurs because the characteristics of the overall system are not considered. Characteristics, such as the environment and temperature, material stiffness adjusted to the application load, surface area, material's transmissibility, pad design techniques and shape factor conformity, are essential to ensure the selection of an anti-vibration material to achieve all the required results.

-

The use of cork to achieve better results

The solutions developed by Amorim Cork Composites for the power industry are based on specific polymer formulations with cork. By combining cork with other materials, that are waste materials from other industries, we give life to new materials and create new products, while simultaneously taking care of the planet.

Cork is a 100% natural, renewable and recyclable raw material, whose characteristics include elasticity, vibration control, chemical resistance, shock absorption. flexibility, installation and process friendly, impermeable to liquids, thermal resistance and performance.

Cork’s closed cell structure, filled with air, contributes to the damping function by dissipating vibration energy, resulting in higher energy loss factors when compared to 100% rubber materials. This dissipation of vibration energy leads to noise reduction, longer machine or tooling life and no transmission to the surroundings.

-

The presence of cork in these solutions also has a positive impact on the shape factor comparing to rubbers. While rubbers are considered incompressible and require space to displace the compressed volume, the rubber-cork formula developed by Amorim Cork Composites displaces much less volume, due to the internal compression of cork (lower Poisson ratio), allowing for a wider shape factor tolerance, which affects the overall robustness of the design.

Casos de Estudo

-

Case Study 1

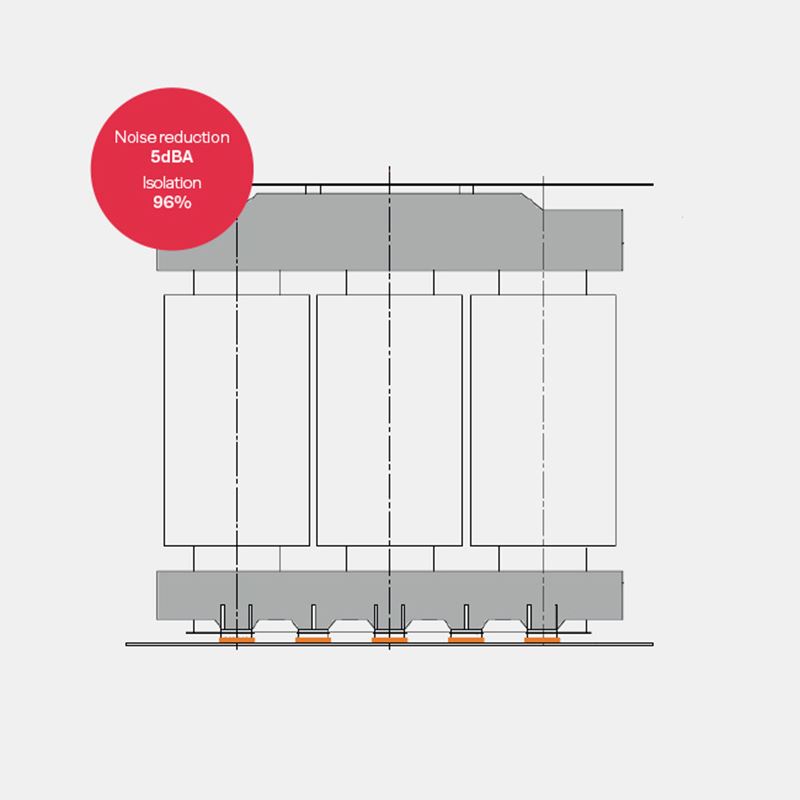

Application: Power transformer (40MVA) weighing 32tons exposed to the environment with an initial noise level of 62dBA

Goal: Reduce the noise level by 3dBA

Solution: Sizing of the anti-vibration PAD, using the Amorim T&D VC6400 solution, measuring 900x200x40mm. This solution was chosen because it is an outdoor application in contact with the environment.

After the application of the solution, the power transformer delivered a 5dBA reduction in the noise level, a very significant improvement when compared to the reference value.

-

Case Study 2

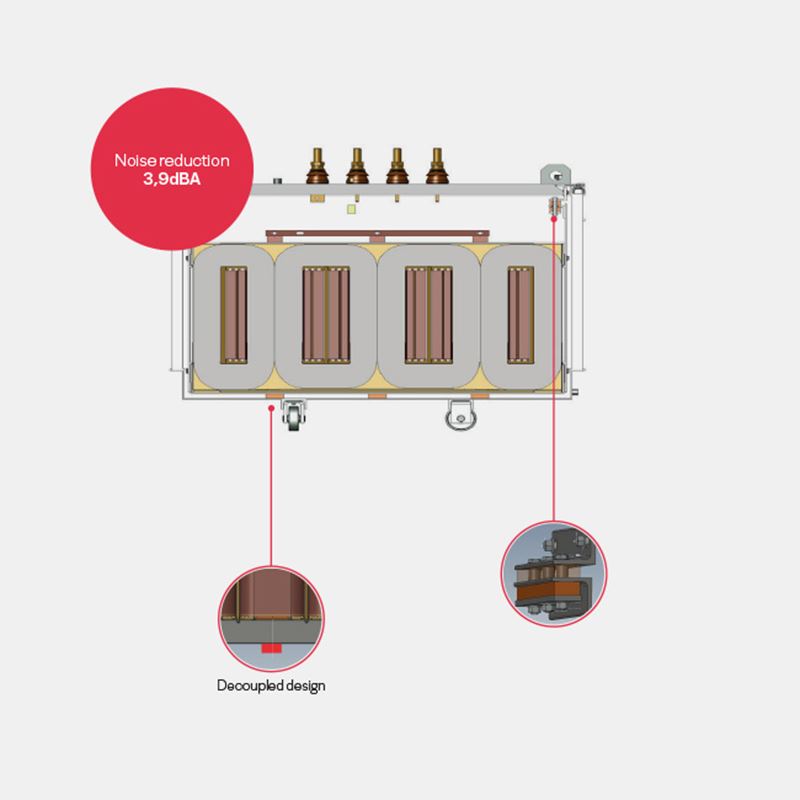

Application: Distribution transformer in contact with oil

Goal: Reduce noise and vibration level

Solution: After an evaluation of the transformer's internal structure (active part), in order to identify the noise sources, Amorim T&D VC2100 was introduced as an anti-vibration PAD and core clamp decoupling solution. This solution delivered a 3.9dBA reduction in the transformer noise level.

Did you know that…

…cork achieves the technical performance required by the market while maintaining its sustainability credentials, given that cork oak trees are important natural carbon retainer?

It is estimated that per each ton of cork produced, the cork oak forest can sequester up to 73 tons of CO₂.